Most of us have used ladders and probably have one in our home or workplace. The step frame ladder is a common choice for the office, lab, shop and studio work areas. Maintenance personnel will often use extension ladders in addition to step ladders. In our familiarity with ladders we incorrectly assume they are safe to use. In fact they are one of the most unsafe pieces of equipment to use.

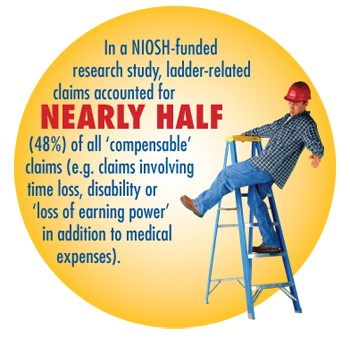

The Consumer Product Safety Commission reports that 90,000 people receive emergency room treatment each year for ladder-related injuries and 300 deaths occur because of a ladder related accident. How can you avoid becoming one of these statistics? Become a trained Ladder User. Learn how to avoid common mistakes when using ladders and protect yourself from an injury.

Step Ladder

Extension Ladder

Training for Ladder Users - Personnel who use ladders need to be trained on how to use and set up the ladder safely and how to inspect it before use to ensure the ladder is in good working order. EHS has developed an online Ladder Safety training module that covers these topics and best work practices.

Fall Protection - Ladder Safety (log-in).

Please be sure to assign this training to your personnel who use ladders.

Extensions provide a safe transition to roof

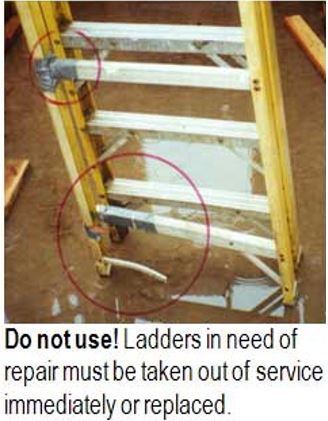

Ladder Safety Inspections - Step frame and extension ladders, made of wood or metal, need to be inspected before they are used. You do not want to be on a ladder working at heights and have it suddenly fail and put you at risk of an injury. Always remove a defective ladder promptly from service. Defective ladders should be tagged as Dangerous, Do Not Use and repaired or destroyed. Consult the ladder manufacturer’s User Instructions, inspection criteria and all warning labels posted on the ladder. Be sure all posted ladder warning labels are visible. If warning labels are illegible, consult the ladder manufacturer for new labels.