The purpose of the following guidance is to provide University of Virginia (UVA) researchers who work with or intend to work with nanomaterials information regarding key environmental health and safety implications and to help facilitate their safe use.

Nanotechnology: The National Nanotechnology Initiative defines nanotechnology as "science, engineering and technology conducted at the nanoscale, which is about 1 to 100 nanometers" It goes on to say "At the nanoscale, the physical, chemical, and biological properties of materials differ in fundamental and valuable ways from the properties of individual atoms and molecules or bulk matter". For context, consider that the diameter of DNA is in the 2.5 nanometer range (a nanometer is 10-9 m, or one-billionth of a meter).

Naturally Occurring Nanomaterial: Matter at this scale is not new and exists in nature, such as particles that make up smoke, and in the biological realm as viruses. In the health and safety realm, nanoscale materials are often referred to as "ultrafine particles". There have been documented instances of negative health outcomes for people exposed to nanoscale materials. The focus of EHS’s guidance, however, is the on the environmental health and safety implications of working with engineered nanomaterials created for research purposes.

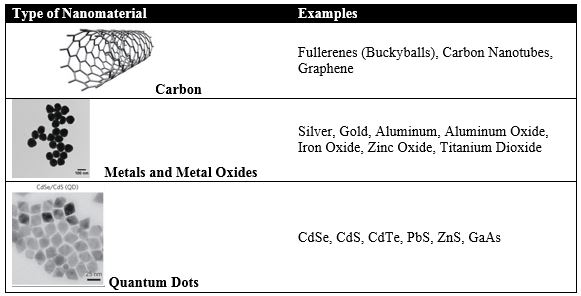

Engineered Nanomaterial: Engineered nanomaterial is intentionally produced material with any external dimension that is nanoscale.

"A growing body of evidence indicates that exposure to some of these engineered nanomaterials can cause adverse health effects… The toxicity of a nanoparticle will be a function of its substance-specific toxicity, as influenced by physicochemical characteristics (including those unique to the nanoscale form of the substance) and contaminants". (National Institute for Occupational Safety and Health (NIOSH), 2012)

Nanomaterials have many commercial applications, including electronic, biomedical, pharmaceutical, cosmetic, energy, and advanced materials. Federal organizations continue to increase their investment in nanotechnology research; with new innovations using nanomaterials, there is potential for unforeseen environmental issues or occupational hazards. Considering that the long-term health and environmental implications for exposure to engineered nanomaterials is not yet well characterized, researchers using nanoscale materials should take steps to limit their exposure.

Yes, engineered nanomaterials can be worked with safely by taking into account the properties of the materials, and taking a methodical approach to managing the risk of exposure. It is important that researchers who intend to work with nanomaterials take the time to make a plan to address the unique problems nanomaterials pose.

Hazard identification can be difficult due to the variable nature of the physicochemical characteristics of each nanomaterial; however, the smallness of nanomaterials does inform the approach to minimizing risk.

The small size of nanoparticles lend themselves to being suspended in air, if present in the form of fine particles; it is for this reason that inhalation is generally considered the primary concern when evaluating routes of exposure. Skin exposure and the passing of nanomaterials into the blood-stream is another serious concern.

The severity of the exposure depends on the state of the material. Free nanoparticles suspended in the air pose a much greater inhalation hazard than nanoparticles which are wetted in a liquid suspension, or bound in a ceramic or polymer matrix.

The potential health risk following exposure to a substance is generally associated with the magnitude and duration of the exposure, the persistence of the material in the body, the inherent toxicity of the material, and the susceptibility or health status of the person.

The uncertainties regarding health risks with exposures to nanomaterials arise because of the gaps in knowledge about routes of exposure, the fate of these materials once they are inside the body, and the variability of toxicity of the nanomaterials. Because of these uncertainties, it is important that precautionary measures be taken to minimize exposures.

Often the information contained in a safety data sheet (SDS) is more relevant to the properties of the bulk material, rather than the nanoscale material; as such, the information, while valuable, may not provide the most accurate or helpful information. Since the potential health effects from exposure to nanoparticles are not fully understood, it is important to follow the precautionary principles and use procedures that minimize all routes of exposure (inhalation, skin contact, and ingestion).

If you work with or plan to work with nanoscale materials, you may contact EHS at 982-4911 for a laboratory consult. By observing your specific laboratory practices, we can provide you with customized recommendations to minimize safety and environmental implications. Accordingly, the following general guidelines are provided to aid personnel in conducting safe, environmentally responsible research activities:

In the case of a spill, avoid activities that may further create airborne nanoparticles, such as sweeping. Instead utilize wet methods or a HEPA filtered vacuum. Please contact EHS at 982-4911 if you are uncertain how to proceed.

Any nanomaterial, waste containing nanomaterials, and wet wipes used to clean contamination shall be disposed of through EHS with a description of the nanomaterial and any associated waste. The following link can be used to submit a request for waste pick up or empty waste containers.

Nanomaterial Waste pickup & new container request - online form (log-in)

There are a number of resources available online that provide information on current research on the toxicity of nanomaterials and current best practices when working with nanomaterials. The list of websites and articles of interest is not exhaustive. Anyone conducting nanomaterial-related research on grounds may contact EHS, so that we may observe laboratory practices and assist personnel in evaluating any processes with potential for exposure. If you have questions or concerns about nanomaterial research, contact EHS at 434.982.4911.

General Safe Practices for Working with Engineered Nanomaterials in Research Laboratories - DHHS/CDC/NIOSH

Good Nano Guide – Collaborative platform specifically designed to enhance the ability to exchange ideas on how best to handle nanomaterials in an occupational setting.

Nanotoolkit - Working Safety with Engineered Nanomaterials in Academic Research Settings, Document created by the California Nanosafety Consortium of Higher Education

National Institute for Occupational Safety and Health (NIOSH) - Nanotechnology Topic Page

The National Nanotechnology Initiative (NNI) - Federal R&D program established to coordinate the multiagency efforts in nanoscale science, engineering, and technology