A qualified person is one who has received training in and has demonstrated skills and knowledge in the operation of electric equipment and installations, and the hazards involved. They must also demonstrate the ability to perform duties safely, including:

Live parts must be deenergized (free from any electrical connection) prior to working on or near them. The safest way to avoid the risks of shock, electrical burns, arc flash and electrocution while working on electrical equipment or facility electrical systems is to shut down the electrical power from the energy source. Refer to Lock Out Tag Out.

The only instances where energized work is considered are those scenarios where it can be demonstrated that additional hazards are created by de-energizing equipment. Examples of additional hazards include, but are not limited to, interruption of life-support equipment, deactivation of emergency alarm systems, and shutdown of hazardous ventilation equipment.

An Energized Electrical Work Permit must be submitted and approved prior to any energized work being completed for everyone at UVA. Note: Justification should only be approved if de-energizing would interrupt essential life support, emergency alarms or ventilation systems.

Live parts that operate at less than 50 volts to ground need not be deenergized if it is determined that there will be no increased exposure to electrical burns or explosion due to electric arcs. Remember, LOW VOLTAGE DOES NOT MEAN LOW HAZARD!

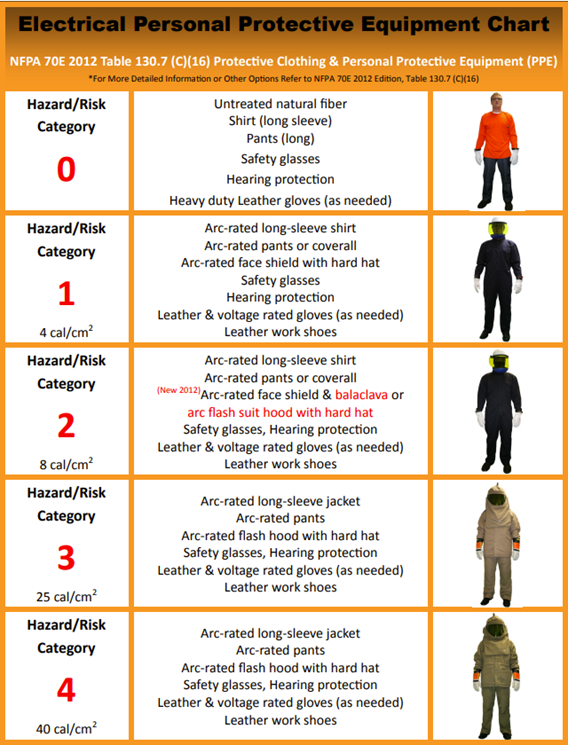

The nature of electrical work determines the type of PPE required. For instance, high-voltage work demands more robust PPE, such as arc flash suits. The minimum required PPE (less than 1.2 cal/cm2) worn when exposed to energized conductors is cotton long sleeve shirts and long pants, eye protection, safety footwear, insulating (rubber) gloves along with leather protectors. Voltage-rated gloves with leather protectors must be worn where there is a danger of electric shock due to contact by the hands. Gloves shall be third party, dielectric tested before first issue and every 6 month thereafter.

All other PPE should be selected based on the specific hazards present and the voltage levels involved. Refer to your FM Electrical Training for more specific information.

Individuals are required to take electrical safety training prior to the following activities:

Training focuses on the hazards of electricity, including components specific to arc flash hazards, proper use of PPE, as well as how to identify and prevent possible accidents and/or injuries.

Contact EHS at 434.982.4911 for any questions or guidance.