Your building may be equipped with a large vacuum system that serves all of the laboratories. Users of building vacuum systems must understand its limitations and use the system as designed. Misuse of the system could result in building-wide vacuum shutdown, or local shut-off.

Chemical contamination or the vacuuming of any fluids, vapors, and debris can severely damage the vacuum system, cause the pump to stop working altogether, emit vapors that can be re-entrained through the ventilation system, and even cause explosions from buildup of flammable vapors.

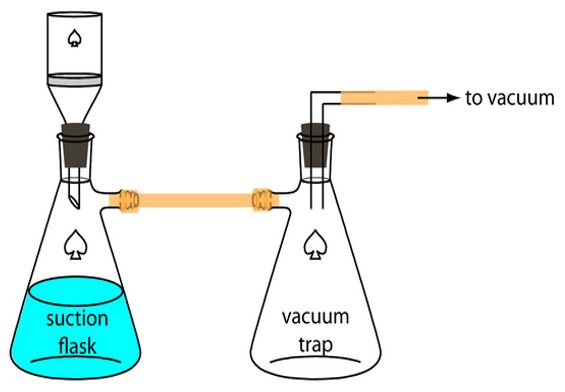

It is important to place a trap between the experimental apparatus and the vacuum source. Depending on what you are working with, there are different types of trap set-ups. The three most common trap set-ups are described below.

When using the vacuum to aspirate water-based systems, install a suction-flask to collect water, and then a vacuum trap. Label the suction-flasks and empty frequently.

If you are going to pull vacuum on any volatile material, set up a cold trap in-line after a suction flask, in order to condense as much of the vapor as possible. See more on cold traps below.

Additionally, experiments involving the use of vacuum for aspiration of human tissue culture or other potentially infectious fluids requires: 1) a vacuum flask containing bleach or other suitable disinfectant to collect contaminated fluids, and 2) an in-line HEPA filter to contain aerosolized biological agents.

Note: Building vacuum systems are not designed to be able to accommodate any amount of liquid or organic vapors. If, for any reason, any amount of liquid is pulled into the system, contact maintenance immediately to ensure that the system can be examined to prevent damage to the equipment. (Academic: 434.924.1777, Health System: 434.924.2267).

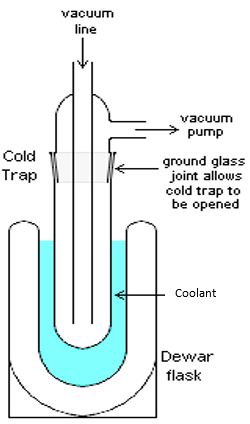

A cold trap is an apparatus that directs the flow of air going to a vacuum pump across a very cold surface. The idea is to condense any vapors, before they make their way into the vacuum-pump, that might otherwise degrade the pump oil or damage the vacuum system.

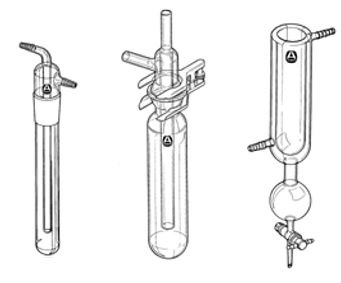

Cold Trapping is typically done using specialized glassware, some examples can be found below.

For a cold source, it is recommended to use a mixture of dry ice and solvent (isopropanol or ethanol are recommended). Use of liquid nitrogen is strongly discouraged. Liquid nitrogen may only be in contact with the trap while the system is sealed or still being evacuated, and then only with extreme caution. If the system is opened while the liquid nitrogen is in contact with the trap, oxygen may condense from the atmosphere. When condensed oxygen comes in contact with organic material (i.e. the liquid collected in the trap) it may create a highly explosive mixture.

When preparing the coolant inside the dewar, add the dry ice slowly to the liquid portion; this will avoid foaming. Dry ice coolants should always be open to the atmosphere, as a closed system will cause dangerous pressure build-up. Carefully lower the trap into the dewar. If running the vacuum for long periods (30+ minutes) you may need to continually add more dry ice.

Check the trap often to ensure that the collected liquid does not freeze and cause a blockage of the trap. If this occurs, you may need to switch your coolant to a higher temperature bath (e.g. ice and salt bath).

When complete, remove the trap from the dewar, shut off the vacuum and slowly vent. Properly dispose of condensed liquid in the cold trap, and the coolant once the dry ice has sublimated.