Machine guarding is used as a precautionary safety feature on machinery and other pieces of equipment. It is a shield or device protecting from accidental contact of body parts with hazardous areas of a machine and can also control hazards like chips and noise from exiting the machine.

Moving parts, sharp edges, and hot surfaces can cause serious injuries such as crushed fingers or hands, amputations, burns, or blindness. Safeguards are essential to eliminate injuries. Any machine part, function, or process that might cause injury should be safeguarded. When the operation of a machine may result in a contact injury to the operator or others in the area, the hazard should be removed or controlled

According to OSHA, machine guarding is the first line of defense to protect workers from machine-related injury. Without guarding, workers would be directly exposed to serious and potentially life-threatening hazards. They also state: "Employee exposure to unguarded or inadequately guarded machines is prevalent in many workplaces. Consequently, workers who operate and maintain machinery suffer approximately 18,000 amputations, lacerations, crushing injuries, abrasions, and over 800 deaths per year. Amputation is one of the most severe and crippling types of injuries in the occupational workplace, and often results in permanent disability."

University labs, makerspaces and shops are also vulnerable to these hazards. In 2011, a Yale student was killed using a lathe that had no guards or emergency stop. The investigation resulted in an OSHA Letter of Recommendations.

These guidelines apply to faculty, staff, and students whose work duties or studies require them to utilize equipment in machine shops or require them to work with portable power tools. It includes all University departments and shop areas that have machinery and equipment capable of causing injury. Shop areas include those used for the purpose of teaching as well as performing other work-related tasks. Areas with only a few pieces of machinery may not be considered "shops", but the safeguarding requirements still apply.

Yes! Simply put, machine guarding must be attached to the machine where possible and secured elsewhere if for any reason they cannot be attached to the machine. The OSHA requirements for Machinery and Machine Guarding are found in 29 CFR 1910 Subpart O.

Under current OSHA regulations, it is the responsibility of the employer who uses the machines to ensure that all machines comply with the general machine guarding requirements. If a machine is sold without guards, the employer who purchases the equipment must provide adequate guarding to comply with applicable OSHA standards.

A wide variety of mechanical motions and actions may present hazards to workers operating or working around machinery. The three basic types of hazardous mechanical motions and actions are:

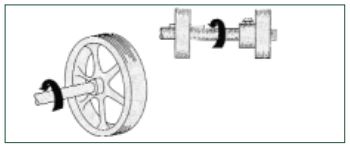

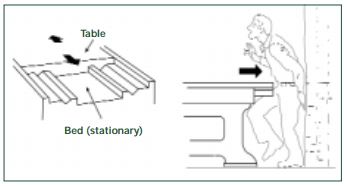

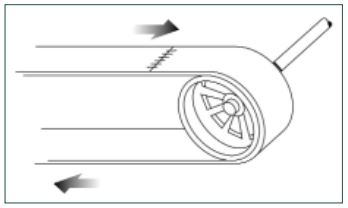

Hazardous Motions – including rotating machine parts, reciprocating motions (sliding parts or up/down motions), and transverse motions (materials moving in a continuous line).

Rotating Motion

Reciprocating Motion

Transversing Motion

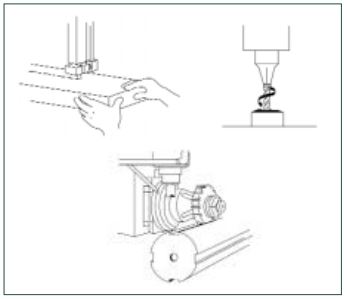

Points of Operation – the areas where the machine cuts, shapes, bores, or bends the stock being fed through it.

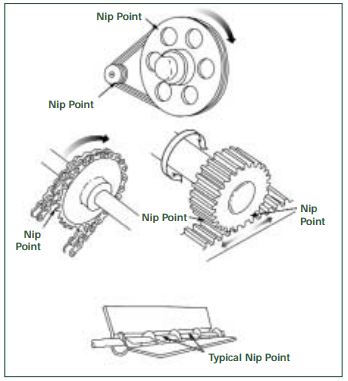

Pinch Points and Shear Points – the area where a part of the body or clothing could be caught between a moving part and a stationary object. This would include power transmission. apparatuses such as flywheels, pulleys, belts, chains, couplings, spindles, cams, gears, connecting rods and other machine components that transmit energy.

There are also non-mechanical hazards that can injure machine operators or personnel working in the vicinity of machinery. These hazards include flying splinters, chips or debris, splashes, sparks, or sprays that are created when the machine is operating. These hazards can be prevented with machine guarding and wearing/use of required personal protective equipment (PPE).

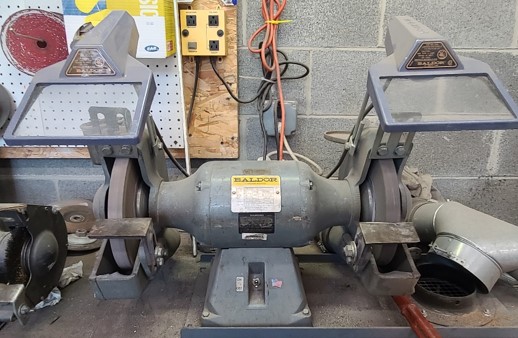

Grinders and Sanders should have shields similar to the ones below.

Drill Press Guarding

Guard for Lathe

OSHA Publication - Safeguarding Equipment and Protecting Employees from Amputations

OSHA Publication - Machine Safeguarding at the Point of Operation

OSHA Publication - Machine Guarding e tool

Manitoba Guideline - Safeguarding Machinery and Equipment

SLAC - Machine Safeguarding Requirements

Contact EHS at 434.982.4911 for any questions or guidance.