Working at elevated heights can put you at great risk if there is no permanent fall protection system in place such as guardrails, a parapet wall on a roof top or catwalk.

Guard Rail at UVA Aerospace Research Laboratory

Guard Rail at UVA Aerospace Research Laboratory

Catwalk in UVA McKim Hall Attic

Catwalk in UVA McKim Hall Attic

Personal fall arrest equipment may be the solution in the event work needs to be done at elevated heights (exceeding four feet from the ground or lower level) and there is no permanent fall protection barrier in place. This guideline covers the ABC’s of fall arrest equipment and proper inspection. Fall arrest equipment is a fall protection system that comprises three major components to reduce the extent of injury in the event of a fall. Let’s begin with the Anchor point. What is an anchor point and who designs or determines the structural stability of an existing anchor point?

Sala Trolley for I Beam Anchor Connector

Sala Trolley for I Beam Anchor Connector

Miller D-Bolt Anchor

Miller D-Bolt Anchor

An anchor point provides a secure point of attachment for fall arrest equipment. The Occupational Safety & Health Administration or (OSHA) requires anchor points to be structurally sound and able to withstand a 5,000 pound static load. That’s the average size of a pickup truck! UVA’s Facilities Management architect and engineering services or Fall Protection engineers are able to assist. They have the professional experience and knowledge to evaluate if existing structural materials will meet this criteria or design new anchor points. Some of the important considerations will be: to install an anchor point where it can be easily accessed without introducing a fall hazard, to install the anchor point where it will be over personnel’s heads to reduce a free fall to accepted limits and prevent environmental factors or dissimilarity of materials from degrading anchor points. Environmental Health & Safety will be happy to coordinate this activity as needed.

The next major component is the full Body harness. The harness is designed to distribute the force across the torso in the event of a fall to reduce the extent of injuries. It is also designed to keep the individual in an upright positon in the event of a fall.

Personnel assigned to fall arrest equipment need to be aware that suspension trauma also referred to as orthostatic intolerance, can occur in the event of a fall and remaining suspended for a prolonged period of time (e.g. awaiting rescue operations). Devices to help alleviate suspension trauma need to be considered. These devices are economical, readily available from fall arrest equipment manufacturers, and are easy to deploy. Consult OSHA's Safety and Health Information Bulletin for more information about the hazards of orthostatic intolerance and suspension trauma when using fall arrest systems.

Individual in Body Harness suspended in upright positon

Individual in Body Harness suspended in upright positon

Individual in Orthostatic Relief Strap

Individual in Orthostatic Relief Strap

UVA Heat Plant personnel in Body Harness

UVA Heat Plant personnel in Body Harness

UVA Drama student in Body Harness

UVA Drama student in Body Harness

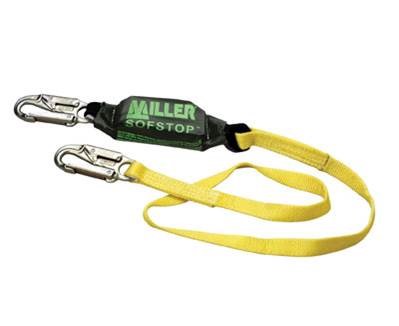

The third major component of the fall arrest equipment system is the Connector. This connects the body harness to the anchor point. The connector is designed to withstand the dynamic forces of a fall to significantly reduce extent of injuries to the individual. Connectors can be a shock absorbing lanyard or a fall limiter, sometimes referred to as a self-retractable lifeline (SRL). The SRL has a quick acting brake that stops a free fall within seconds. It operates similarly to the seat belt in a car. There are advantages and limitations that must be considered to assure the overall safety of personnel wearing fall arrest equipment. The Environmental Health & Safety Fall Protection Competent Person can advise on the most appropriate Connecter for the fall hazard.

Miller shock absorbing lanyard

Miller shock absorbing lanyard

Picture Courtesy of Miller Fall Protection & Safety

Fall Limiter or Self Retractable Lifeline (SRL)

Fall Limiter or Self Retractable Lifeline (SRL)

Picture Courtesy of Miller Fall Protection & Safety

Training Requirements - Personnel using fall arrest equipment at UVA (faculty, staff and students) must be authorized through training including hands-on for the selected equipment by a Fall Protection Competent Person.

See the EHS online training module Fall Protection - Fall Arrest Equipment Orientation (log-in).

This module covers the safe use of FA equipment and how to avoid fall hazards when using the equipment such as proper planning to avoid coming into contact with a lower level and preventing swing fall hazards. The equipment manufacturer’s user instructions must always be consulted and followed.

Fall Arrest Equipment Inspection - Instructions on how to perform FA equipment inspections is clearly detailed in the equipment manufacturer's User's Instruction Manual. Manufacturers will often include photographs to illustrate how to complete a thorough inspection on each component. Special attention is required on each component including the condition of the webbing material, stitching, and metal hardware. Miller by Honeywell fall arrest products are commonly chosen by UVA personnel and they provide step by step guides for inspection.

Visit the Miller by Honeywell site, then select "Training and Support" --> "Resource Library" --> "Technical and Application Notes" --> "Fall Protection". There you will find the link to download the Miller Product Inspection Guide.

Remove Defective Equipment Immediately from Service - Occupational Safety & Health Administration (OSHA) and the equipment manufacturer require any equipment with defects, deterioration or subject to the forces of arresting a fall to be immediately removed from service. Destroy the equipment to prevent accidental use that can endanger someone’s life.

Document Equipment Inspection - Equipment Inspections need to be documented by the User prior to use!

Equipment Manufacturers provide inspection logs either in the User's manual or on an attached inspection tag on the equipment, these should be used to document pre-use inspections. In addition to pre-use inspections, annual equipment inspections must be performed and documented by a Fall Protection Competent Person (FPCP). The Facilities Management Fall Protection Checklist can be used for documentation. If the department does not have a designated FPCP you must consult with EHS Fall Protection staff to assist you.

UVA Drama personnel documents equipment inspection

UVA Drama personnel documents equipment inspection